Product Description:

Features:

-

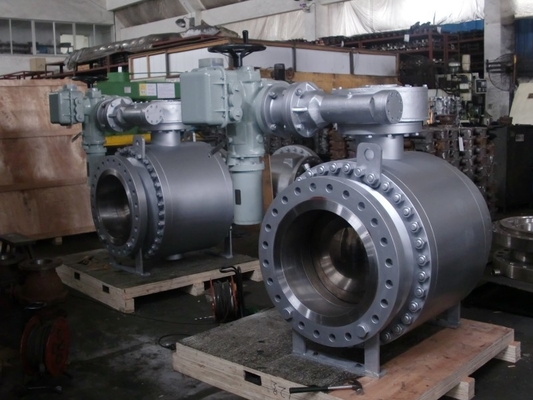

Product Name: Trunnion Ball Valve

-

Type: Trunnion mounted valve

-

Ball Material: Stainless Steel

-

Body Material: Carbon Steel

-

Anti-Static: Yes

-

Blowout Proof: Yes

-

Operation: Manual

Technical Parameters:

|

Application

|

Oil and Gas

|

|

Operation

|

Manual

|

|

End Connection

|

Flanged

|

|

Anti-Static

|

Yes

|

|

Blowout Proof

|

Yes

|

|

Pressure Rating

|

Class 150

|

|

Valve Type

|

Trunnion Ball Valve

|

|

Fire Safe

|

Yes

|

|

Ball Material

|

Stainless Steel

|

|

Stem Material

|

Stainless Steel

|

Applications:

One of the main features of this valve is its fire safe construction. In the event of a fire, the valve will maintain its integrity and prevent the spread of fire by sealing off the flow of fluid. This makes it an ideal valve for applications in industries where there is a risk of fire, such as oil and gas, petrochemicals, and power plants.

The Trunnion Ball Valve is also equipped with a blowout proof design, which ensures that the valve stem will remain in place even under high pressure. This feature prevents the stem from being blown out of the valve, preventing any potential damage or accidents.

This valve is a trunnion mounted design, which means that the ball is supported by two trunnion bearings. This design offers better stability and reduces the amount of torque required to operate the valve. The Trunnion Ball Valve comes in a 16-inch size, making it suitable for various applications that require a larger valve.

Overall, the Trunnion Ball Valve is an excellent product that is suitable for a wide range of industrial applications. Its fire safe construction, blowout proof design, and trunnion mounted ball make it a reliable and durable valve that can withstand the harshest conditions. Industries such as oil and gas, petrochemicals, and power plants can benefit from the excellent performance and durability of this valve.

Support and Services:

The Trunnion Ball Valve is a high-performance valve designed for use in various applications, including petrochemical, chemical, and gas industries. It is designed with a trunnion mechanism that supports the ball to ensure stable operation even at high pressures.

This valve is available in various sizes and materials to meet specific application requirements. It is designed with an anti-blowout stem that prevents the stem from being ejected due to high pressure or temperature. The valve body is designed with a cavity relief system that allows the cavity pressure to be relieved before the valve is opened, reducing the risk of damage to the valve.

Our technical support team is available to provide assistance with any product-related concerns or issues. We also offer a range of services, including valve maintenance, repair, and testing, to ensure reliable and efficient operation of the valve. Contact us for more information on our product technical support and services.

Packing and Shipping:

Product Packaging:

-

The Trunnion Ball Valve will be packaged in a sturdy cardboard box.

-

The valve will be securely wrapped with bubble wrap to prevent any damage during shipping.

-

A user manual will be included in the package.

Shipping:

-

The product will be shipped via a reputable courier service.

-

Shipping times may vary depending on the destination.

-

A tracking number will be provided to the customer upon shipment.

-

Shipping costs will be calculated based on the destination and weight of the package.

FAQ:

A Trunnion Ball Valve is a type of valve that uses a ball to control the flow of fluid through a pipeline. It is designed with a fixed, or stationary, ball and a rotating stem that is supported by bearings, known as trunnions, to reduce friction and ensure smooth operation.

Q: What are the advantages of using a Trunnion Ball Valve?

Trunnion Ball Valves offer several advantages, including high flow capacity, low torque operation, excellent shutoff capabilities, and reduced wear and tear due to their trunnion-mounted design. They are also suitable for a wide range of applications, including oil and gas, chemical processing, and water treatment.

Q: What materials are Trunnion Ball Valves made of?

Trunnion Ball Valves can be made from a variety of materials, including carbon steel, stainless steel, cast iron, and brass. The choice of material depends on factors such as the type of fluid being transported, the temperature and pressure of the application, and the environment in which the valve will be used.

Q: How do I select the right Trunnion Ball Valve for my application?

To select the right Trunnion Ball Valve for your application, consider factors such as the type of fluid being transported, the temperature and pressure of the application, the size and flow rate of the pipeline, and the environmental conditions in which the valve will be used. It is also important to choose a valve that is compatible with the piping system and meets any applicable industry standards.

Q: How do I install and maintain my Trunnion Ball Valve?

To install and maintain your Trunnion Ball Valve, refer to the manufacturer's instructions and follow best practices for valve installation and maintenance. This may include regular inspection and cleaning of the valve and its components, checking for leaks or damage, and lubricating moving parts as needed. It is also important to ensure that the valve is installed correctly and that any necessary safety precautions are taken.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!