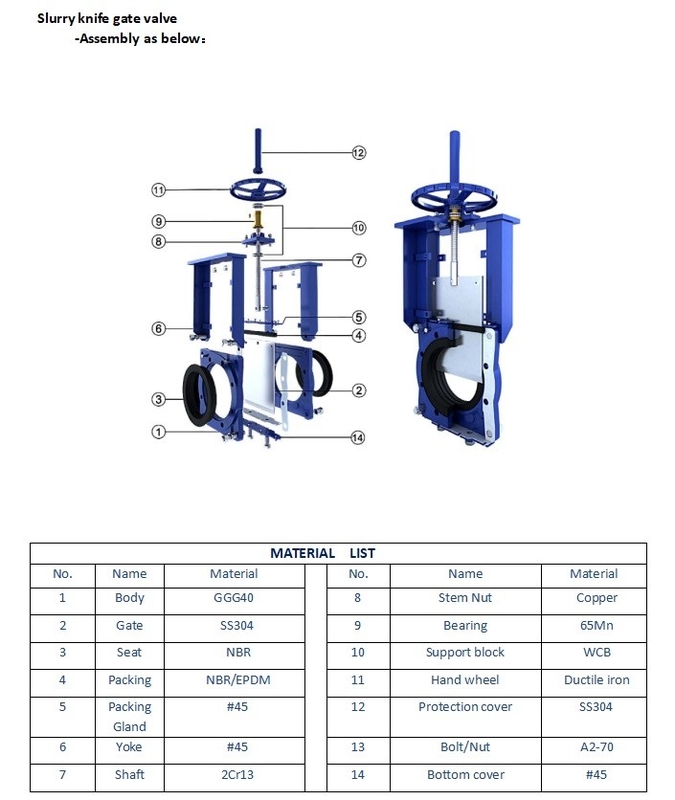

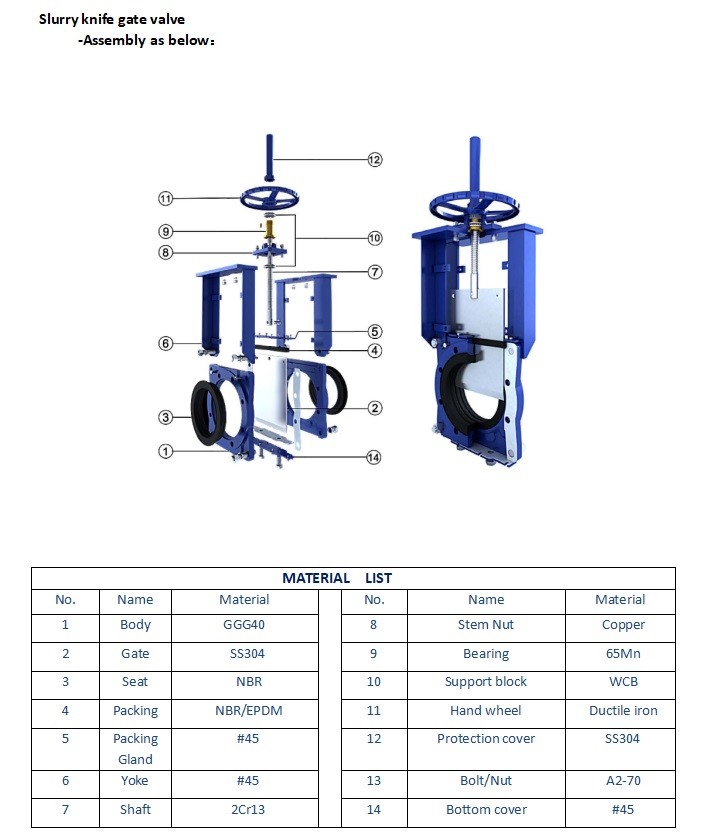

Product Description:

Knife Gate Valve

Knife Gate Valve is a type of Pneumatic Gate Valve designed for applications in various industries such as Slurry, Wastewater, Mining, Pulp and Paper, and Chemical. It is a versatile valve that can handle high flow rates and abrasive materials with ease.

Product Overview

The Knife Gate Valve is available in three different end connections - Wafer, Lug, and Flanged. This allows for easy installation and connection to pipes of different sizes. The valve is also designed with a full port, providing unobstructed flow for better performance.

Model and Type

The standard model of the Knife Gate Valve is the Standard Double Acting Knife Gate Valve. It is equipped with two pneumatic actuators that allow for smooth and precise control of the valve. The valve is also bi-directional, allowing for flow in both directions.

The Knife Gate Valve is classified as a Pneumatic Gate Valve, which means it is operated by compressed air. This makes it suitable for use in hazardous environments as it does not require electricity or manual operation.

Features

- Full Port - The Knife Gate Valve has a full port design, ensuring unobstructed flow and minimal pressure drop.

- Bi-Directional - The valve is designed to allow flow in both directions, making it versatile and suitable for various applications.

- Metal or Soft Seat - The valve is available with either a metal or soft seat, depending on the application and the type of fluid being handled.

- Low Emission Packing - The valve is equipped with low emission packing, which reduces the amount of leakage, making it more environmentally friendly.

Application

The Knife Gate Valve is suitable for a wide range of applications, including:

- Slurry - The valve can handle high flow rates and abrasive materials, making it ideal for use in slurry applications.

- Wastewater - The valve is designed to handle wastewater and can withstand harsh chemicals and corrosive substances.

- Mining - The valve is commonly used in the mining industry for handling minerals and other materials.

- Pulp and Paper - The valve is suitable for use in the pulp and paper industry for handling various types of fluids and chemicals.

- Chemical - The valve is designed to withstand a wide range of chemicals, making it suitable for use in the chemical industry.

Conclusion

The Knife Gate Valve is a reliable and versatile valve that can handle a variety of fluids and materials. With its full port design, bi-directional flow, and low emission packing, it is a cost-effective solution for various industries. Its pneumatic operation also makes it a safe and efficient choice for hazardous environments. Choose the right end connection and seat option, and the Knife Gate Valve will deliver excellent performance for your application needs.

Features:

- Product Name: Knife Gate Valve

- Pressure Rating: Class 150 - Class 300

- Application: Slurry, Wastewater, Mining, Pulp and Paper, Chemical

- Body Material: Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel

- Actuation: Double Acting

- Design Standard: API 600, API 6D

- Stainless Steel Knife Gate Valve

- Slurry Gate Valve

- Stainless Steel Knife Gate Valve

- Wastewater Valve

Technical Parameters:

| Model |

Standard Double Acting Knife Gate Valve |

| Temperature Range |

-20°F to 450°F |

| Design Standard |

API 600, API 6D |

| Valve Type |

Knife Gate Valve |

| Features |

Full Port, Bi-Directional, Metal or Soft Seat, Low Emission Packing |

| Actuation |

Double Acting |

| End Connections |

Wafer, Lug, Flanged |

| Seat Material |

EPDM, NBR, Viton, PTFE |

| Size Range |

2" - 48" |

| Application |

Slurry, Wastewater, Mining, Pulp and Paper, Chemical |

Other keywords: Pneumatic Knife Gate Valve, Slurry Knife Gate Valve, Wafer Gate Valve, Bi-directional Knife Gate Valve, Soft Seat Knife Gate Valve, EPDM Knife Gate Valve, NBR Knife Gate Valve, Viton Knife Gate Valve, PTFE Knife Gate Valve

Applications:

Knife Gate Valve

Knife Gate Valve is a type of industrial valve that is specifically designed for handling tough and abrasive substances. It is widely used in various industries such as mining, pulp and paper, chemical, and wastewater treatment.

The valve is designed with a sharp-edged gate or blade, which can cut through thick and heavy materials. This unique design allows for a tight seal and easy flow control, making it ideal for applications that involve high pressures and large particle sizes.

Product Attributes

- Pressure Rating: Class 150 - Class 300

- Seat Material: EPDM, NBR, Viton, PTFE

- Temperature Range: -20°F to 450°F

- Valve Type: Knife Gate Valve

- End Connections: Wafer, Lug, Flanged

Application and Scenarios

The following are some of the common applications and scenarios where Knife Gate Valves are used:

- Mining: In the mining industry, Knife Gate Valves are used for controlling the flow of slurries containing minerals, ores, and other materials. These valves are specially designed to withstand high pressures and abrasive substances, making them suitable for use in harsh mining environments.

- Pulp and Paper: Knife Gate Valves are commonly used in the pulp and paper industry for controlling the flow of wood chips, paper pulp, and other fibrous materials. The sharp-edged gate of the valve ensures a tight seal, preventing any leakage or blockage in the process.

- Chemical Industry: Chemical processing plants often deal with corrosive and abrasive substances, which require a valve that can withstand such harsh conditions. Knife Gate Valves made of stainless steel are perfect for handling these materials and ensuring smooth flow control.

- Wastewater Treatment: Sludge and other solid materials are often found in wastewater treatment plants. Knife Gate Valves are used in these facilities to control the flow and prevent clogging or blockage in the pipes. The wafer gate valve design is particularly useful in this application as it takes up less space and is more cost-effective.

Product Range

Knife Gate Valves are available in a wide range of sizes and materials to suit different applications and operating conditions. The most common materials used for the body of the valve are stainless steel and cast iron, while the gate is usually made of stainless steel, carbon steel, or other high-strength alloys.

The valve is also available in various pressure ratings, ranging from Class 150 to Class 300, making it suitable for a wide range of industrial processes.

Conclusion

In summary, Knife Gate Valve is a versatile and robust valve that is suitable for handling tough and abrasive substances. Its unique design and various product options make it a popular choice for applications in different industries. Whether it's controlling the flow of slurry, pulp, or other solid materials, Knife Gate Valves are an excellent choice for reliable and efficient flow control.

Packing and Shipping:

Packaging and Shipping for Knife Gate Valve

The Knife Gate Valve will be packaged in a sturdy cardboard box to ensure safe delivery. The box will be filled with protective materials such as bubble wrap or foam to prevent any damage during transportation.

The dimensions of the box will vary depending on the size of the valve, but it will be compact and lightweight to minimize shipping costs.

The valve will be securely sealed and labeled with handling instructions and product information for easy identification.

For shipping, we offer several options including air freight, sea freight, and land transportation. We work with trusted logistics partners to ensure timely and efficient delivery to our customers.

For international shipments, necessary customs and export documentation will be included to comply with regulations and facilitate smooth customs clearance.

Our company takes great care in packaging and shipping our products to ensure they arrive at their destination in excellent condition.

FAQ:

- Q:What is Knife Gate Valve?

A:Knife Gate Valve is a kind of valve with a sharp blade, which can cut off the fluid by moving up and down along the vertical direction.

- Q:What is the material of Knife Gate Valve?

A:The main materials of Knife Gate Valve are stainless steel, cast iron, and carbon steel.

- Q:What is the working temperature range of Knife Gate Valve?

A:The working temperature range of Knife Gate Valve is -20°C to 100°C.

- Q:How does Knife Gate Valve work?

A:Knife Gate Valve works by using a sharp blade to cut off the fluid flow and control the flow rate.

- Q:What are the advantages of Knife Gate Valve?

A:Knife Gate Valve has the advantages of compact structure, small size, and easy maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!